News

PIERRET – MANUFACTURER OF WINDOWS AND DOORS – CASE STUDY

Concept:

For more than 60 years, Pierret, – the Belgian window and door supplier has been supplying a wide range of window and door products manufactured from various materials – PVC, wood and aluminium. As production has expanded, the customer has successively increased the amount of material stocked, necessary to ensure a smooth supply. The large number of different window profiles stored on cantilever racks and transported by forklift constantly increased the time needed to complete the profiles for further processing in the paint shop.

The aim of the project to automate the storage and internal transport of profiles was to reduce as much as possible the time needed to complete orders and transfer them for further processing.

Solution:

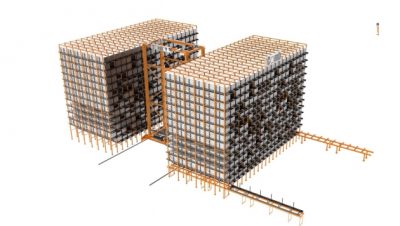

The proposed solution is an integrated system: the LogiComb warehouse together with the 4-tower LogiTower system, which fulfils the customer’s burning need – to speed up order picking for the paint shop and optimise material flow in production.

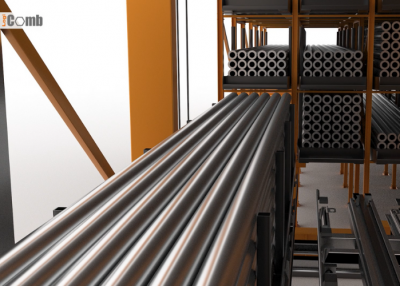

For the client, the optimum solution was a LogiComb system in the form of 1 column of cassettes, operated by 1 crane. The automated system was placed in a new hall, added to the company’s existing infrastructure, linking the buildings and shelving by access windows. The 801 locations (7300mm x 800mm x 300mm) in the LogiComb system provide efficient storage and management of the raw material for window production – profiles of different cross-sections and applications.

LogiComb is equipped with 3 access points, allowing several operators to work simultaneously and increasing productivity and speed. The edge access window is exclusively dedicated to feeding the racking with goods directly from the delivery truck. This solution isolates the loading area and increases safety at the picking stations .

The order arrives at the paint shop on the overhead conveyor system via two possible routes: for serial orders directly from the access window of the LogiComb system, for non-standard orders from the LogiComb system first to the buffer warehouse – the 4 towers of the LogiTower system. In both cases, the profiles reach the access point at an ergonomically convenient height for the operator, from where they are manually transferred to the overhead transport system and then directly to the paint shop. By eliminating the use of a forklift, positioning the profile warehouse in close proximity to the paint shop and ensuring an ergonomic order picking process, the time required to process a large number of orders at the same time was reduced.

Both LogiTower and LogiComb were integrated with the customer’s internal ERP system, enabling a seamless flow of information between the warehouse and production and optimising the distribution of profiles in the racks.

Benefits:

The use of the LogiComb system together with the LogiTower system allowed the customer to reduce order picking times for the paint shop and optimise material management. Thanks to the multiple access points, the flexibility to adapt to the space and the ergonomic layout, operators can work simultaneously, increasing productivity and safety in the storage and picking process of window profiles.