SHEET METAL, MOLD, LONG-BAR & UNTYPICAL OR HEAVY GOODS automated storage system

– design and production –

SHEET METAL, MOLD, LONG-BAR & UNTYPICAL OR HEAVY GOODS automated storage system

– design and production –

SHEET METAL, MOLD, LONG-BAR & UNTYPICAL OR HEAVY GOODS automated storage system

– design and production –

SHEET METAL,MOLD, LONG-BAR & UNTYPICAL OR HEAVY GOODS automated storage system

– design and production –

SHEET METAL, MOLD, LONG-BAR & UNTYPICAL OR HEAVY GOODS automated storage system

– design and production –

SHEET METAL, MOLD, LONG-BAR & UNTYPICAL OR HEAVY GOODS automated storage system

– design and production –

LogiTower is an advanced solution for automated storage systems as well as production automation and internal transport of heavy goods. Our systems are designed to deliver maximum space utilization, optimized working time, and increased efficiency of industrial processes.

Main applications:

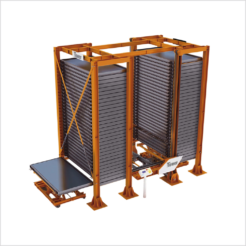

1) Automated sheet metal storage system – LogiTower

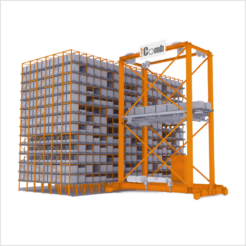

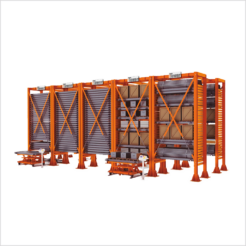

2) Automated storage racks for window profiles, bars, and long goods – LogiComb

3) Robotization of storage and loading processes for heavy tools, injection molds, and dies – Single-tower LogiTower or Double-tower LogiTower

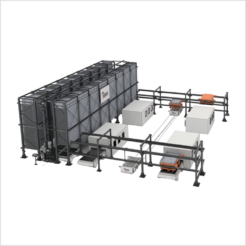

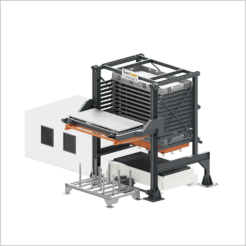

4) Automatic sheet metal loading and unloading system – LogiTowerLoader

The LogiTower product family includes:

1) Storage systems: LogiTower, MultiLogiTower, and LogiComb (a honeycomb-type storage system),

2) Automatic loading systems: LogiTowerLoader and InLoader, designed to cooperate with laser cutting machines (e.g. fiber laser systems), significantly reducing production time and optimizing internal logistics.

Thanks to LogiTower, it is possible to fully utilize the height of the production or warehouse hall, increase workplace safety, improve ergonomics, and take automation and robotization to a new, higher level.

Our Products

.

LogiTower double tower sheet metal storage

LogiTower single tower long goods storage

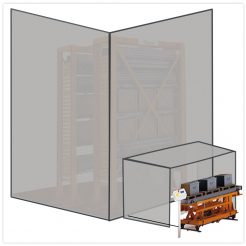

LogiTower Loader Basic, Advanced, Complex

LogiTower Loader Compact

Inloader – semi-automatic sheet metal loading system

LogiComb – honeycomb system

LogiTower single tower sheet metal storage

MultiLogitower with stacker crane

LogiTower – double tower for molds

LogiTower double tower long goods storage

Logitower double-sided storage system

LogiTower with side station

LogiTower – Outside loading

Logitower outdoor storage

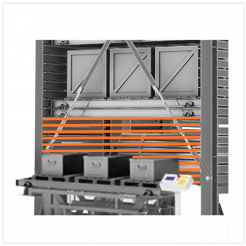

Height Detection Space Optimization

LogiTower control and integration

Applications

Our customers

News

REPORTS, PARTNERS

LogiTower is an AS/RS automatic storage system that enables to store sheet metal, long goods such as pipes, profiles, rods, tubes, as well as heavy and untypical goods such as tools, molds, dies, pallets and many others. Logitower is a technologically advanced storage system that fits into the Intralogistics 4.0 trend.

Ergonomics and saving of storage space

Our solutions for storing sheet metal, rods, profiles, logs, tubes, tools or molds enable to ergonomic, efficient, safe storing and picking heavy goods while taking advantage of a full available room height to save storage space. To minimize its use even more, we have developed the High Detection Space Optimization system, which measures the height of goods and adjusts spacing between shelves to a size of the stored items. The high density of shelves plays a significant role especially in case of a large variety of goods.

How does the Logitower automated storage system work?

The system is based on a vertical lift (extractor) motion, which delivers the shelves with goods directly to an operator. This solution enables to store heavy and bulky goods ergonomically, efficiently and safely, while taking advantage of a full available room height, which saves storage space.

Logitower’s sheet metal, long and unusual goods storage is designed individually for each customer, according to his needs and requirements.

Automation of warehouse processes in your company

Each company has an individual character, just like the Logitower automated storage system we offer. The LogiTower for storing sheet metal, long goods, tools or molds is available in many configurations,such as varied amount of storage towers, including: Single Tower, DoubleTower or MultiLogitower, as well as the varied number of storage shelves, including, among others, Logicomb multi-shelf storage system for profiles, pipes, rods, etc.

Logitower and Logicomb systems cooperate with machining centers, including CNC machines for laser (fiber) or water-jet cutting, as well as manipulators. The integration of our automated storage systems with the company’s ERP/WMS program is also available.

Within many product options available, you can find a double (front and back) access points, side station, as well as outdoor one, which enables, among other, to load items to the Logitower cart directly from a delivery truck.

A great convenience is an opportunity to use a depalletiser, which enables to unload sheet metal and storing them separately from pallets, which additionally increases space saving in a warehouse.

LogiTower is an optimal solution for manufacturers of many industries. This vertical storage system can be used as a storage for sheet metal, long bars, as well as other goods of unusual shapes and high weight, such as injection molds, tubes, heavy tools, and many others.

Safety and security first

LogiTower, providing protection for vulnerable components with large of non-standard dimensions, reduces losses in goods. The system also significantly increases safety of operators machine or forklift operators while performing intralogistics operations.

Storage of metal products: easy and effective

What are the reasons to choose Logitower’s automated sheet metal, long bars and heavy and untypical goods storage system?

Logitower enables an optimal use of every storage space square meter, providing maximum capacity on a minimum space. Each automated storage system can hold up to 8,000 kg of steel, aluminium, copper, plastic and other materials.

The solutions we offer enables to save up to 80% of the warehouse space, as well as time spent on logistics operations. They also eliminate the risk of destroying or damaging sensitive and valuable goods, increasing the ergonomics of work, which also accelerates internal warehouse processes and increases their safety.

The Logitower brand is present on the international market of warehouse automation through, inter alia, a developed network of local distributors. Many Polish and foreign companies have trusted us choosing our system of storing their goods.

Join them now and increase the efficiency of logistics processes in your warehouse!