Inloader handling the sheet metal loading & unloading process by allowing sheet metal to be semi-automatically picked from a stack or rack shelf, loaded into a CNC/FIBER laser cutting center, and then picked up the cut parts.

Download catalog

Inloader handling the sheet metal loading & unloading process by allowing sheet metal to be semi-automatically picked from a stack or rack shelf, loaded into a CNC/FIBER laser cutting center, and then picked up the cut parts.

Download catalog

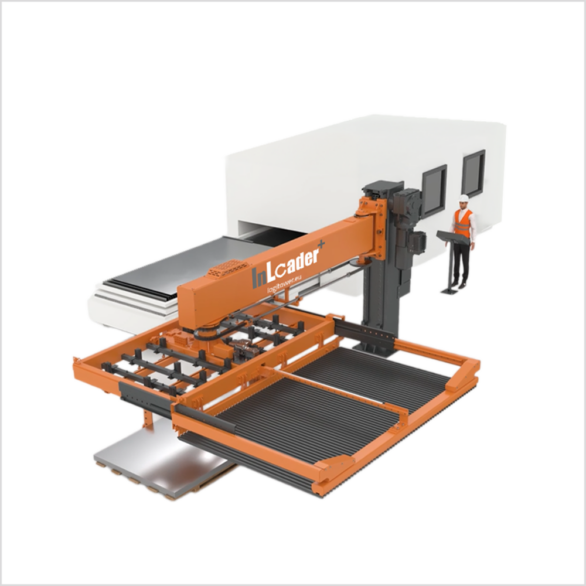

InLoader BASIC – semi-automatic sheet metal loading system

What processes does InLoader Basic provide?

Takes sheets of metal from the stack and separates them magnetically, so we are sure that only one sheet of metal is handled.

Transfers a single sheet of metal from the stack to the laser cutter table.

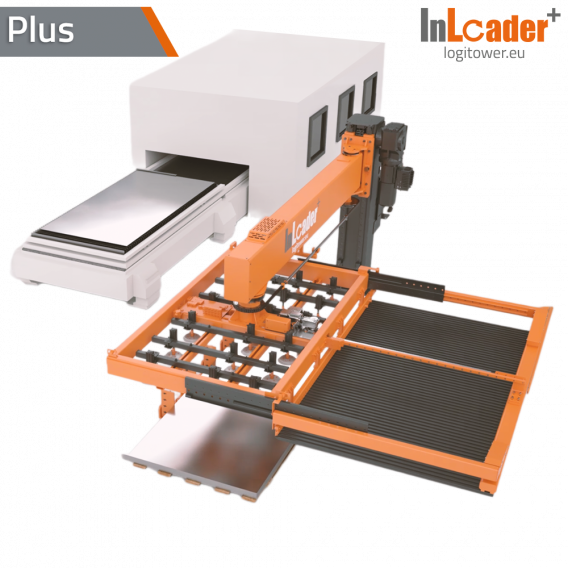

InLoader PLUS – semi-automatic sheet metal loading system

Additional tasks of the InLoader Plus system:

– In addition to supplying sheet metal to the cutting machine, InloaderPlus also provides for the collection of already cut parts from the laser cutting machine table using dedicated forks.

– It moves the cut-out parts to a picking storage point, which can be a pallet or, for example, the cassette of a LogiTower automatic rack, for sorting (either manually or automatically, e.g. with a robot).

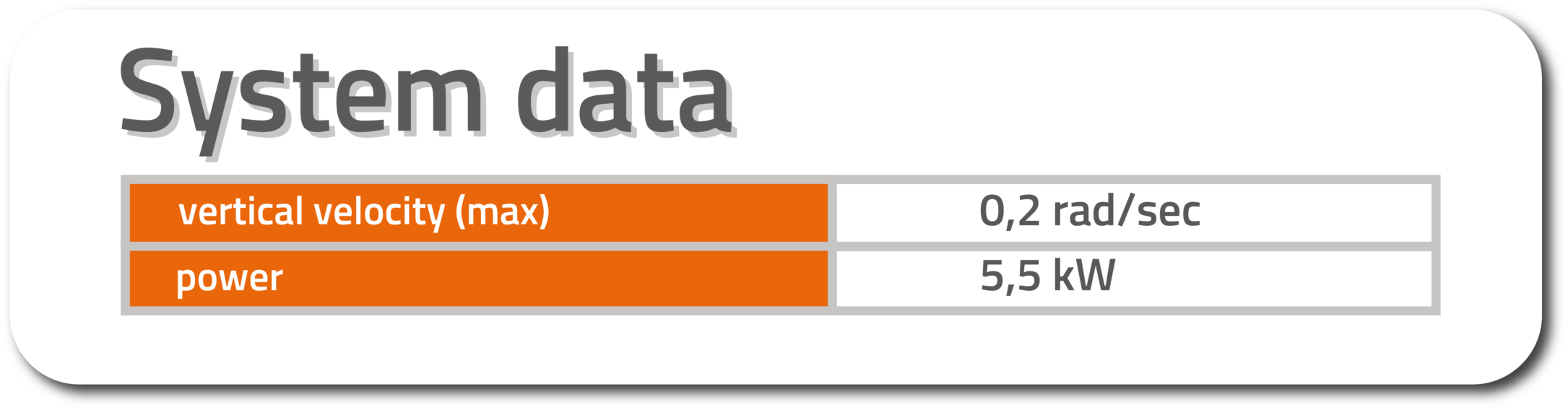

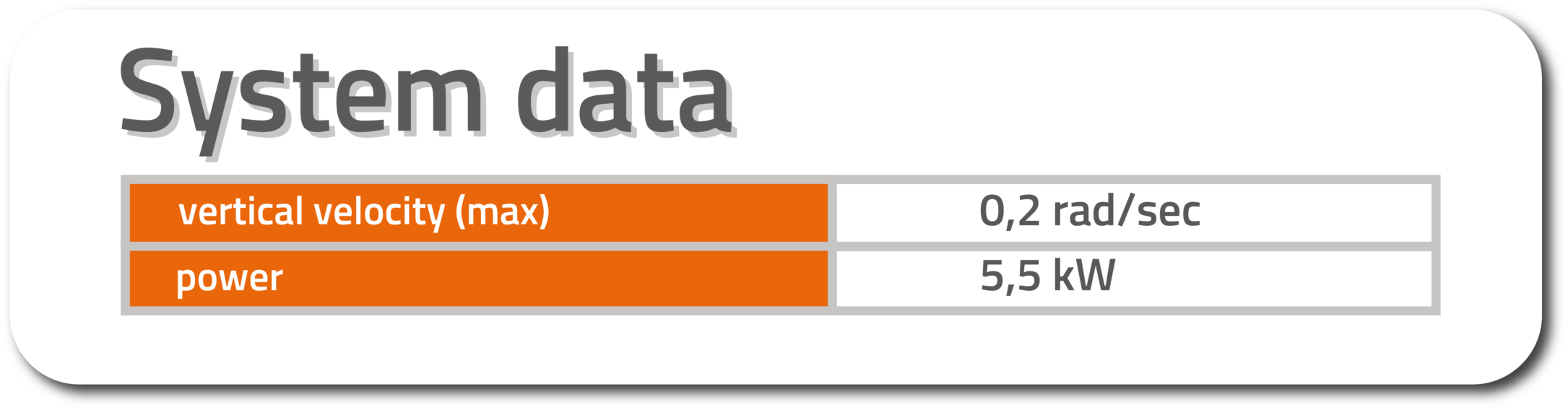

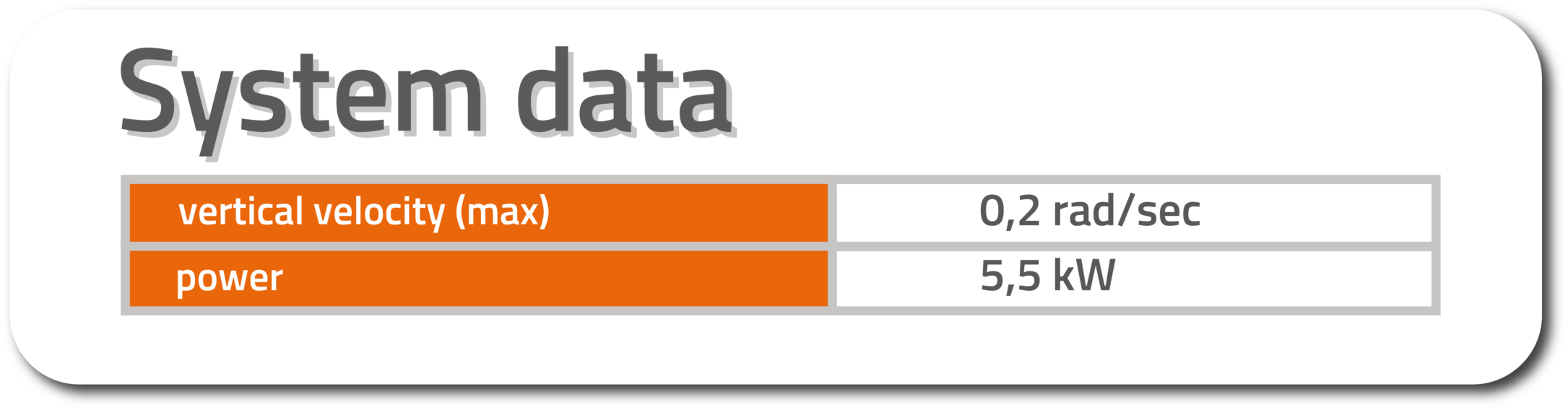

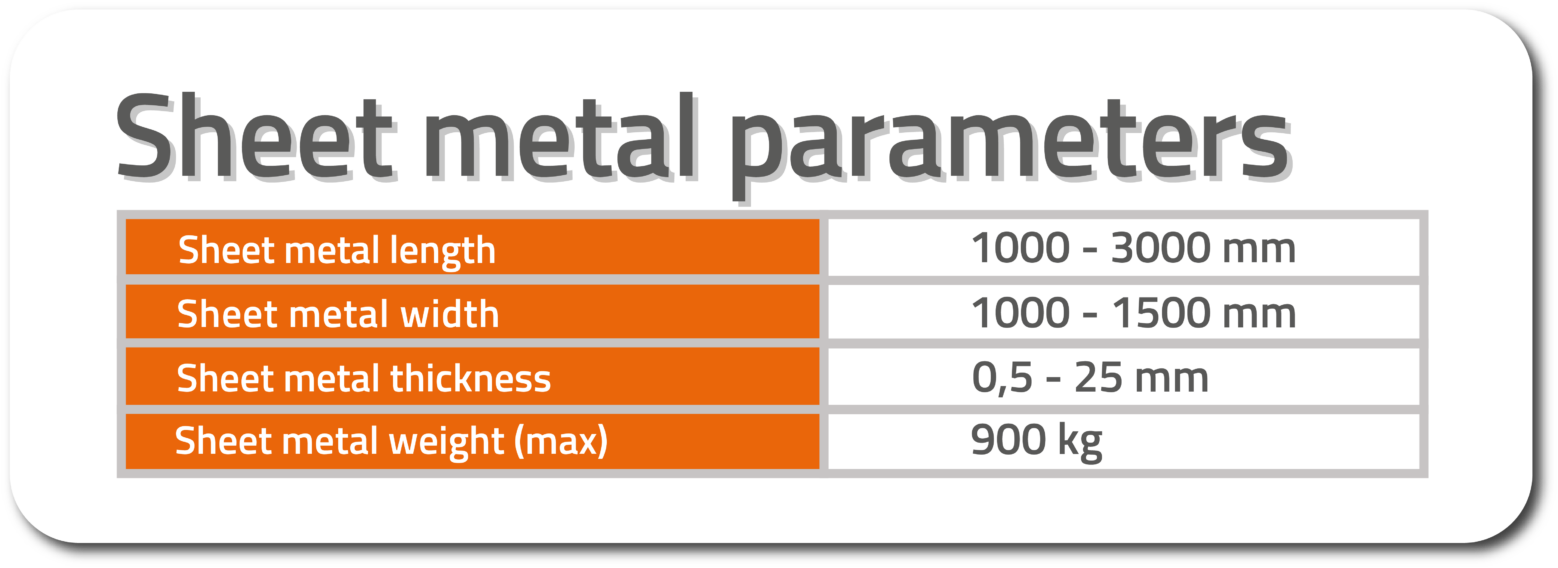

The InLoader features compact dimensions with a maximum vertical movement speed of 0.2 rad/s. It handles sheet metal with a length of 1000-3000 mm, a width of 1000-1500 mm, a thickness of 0.5-25 mm, and a weight of up to 900 kg.

InLoader BASIC – semi-automatic sheet metal loading system

What processes does InLoader Basic provide?

Takes sheets of metal from the stack and separates them magnetically, so we are sure that only one sheet of metal is handled.

Transfers a single sheet of metal from the stack to the laser cutter table.

InLoader PLUS – semi-automatic sheet metal loading system

Additional tasks of the InLoader Plus system:

– In addition to supplying sheet metal to the cutting machine, InloaderPlus also provides for the collection of already cut parts from the laser cutting machine table using dedicated forks.

– It moves the cut-out parts to a picking storage point, which can be a pallet or, for example, the cassette of a LogiTower automatic rack, for sorting (either manually or automatically, e.g. with a robot).

The InLoader features compact dimensions with a maximum vertical movement speed of 0.2 rad/s. It handles sheet metal with a length of 1000-3000 mm, a width of 1000-1500 mm, a thickness of 0.5-25 mm, and a weight of up to 900 kg.

Benefits:

– Integrated suction cup and fork module for precise loading and unloading of sheet metal.

– Fast and safe exchange of material in the laser cutter thanks to a semi-automatic process (human supervision) without the use of other means of transport such as forklifts or cranes. This greatly improves ergonomics and reduces time.

– Reduced risk of damage and scratches to metal sheets.

– Cooperation with laser cutters and other machines from different manufacturers, which does not require integration such as IT.

– Collaboration with LogiTower’s automatic sheet metal warehouses for even greater benefits in terms of saving space, increasing work safety or speeding up the processes involved in storing and picking sheet metal, long-logs, large and heavy parts, and much more.