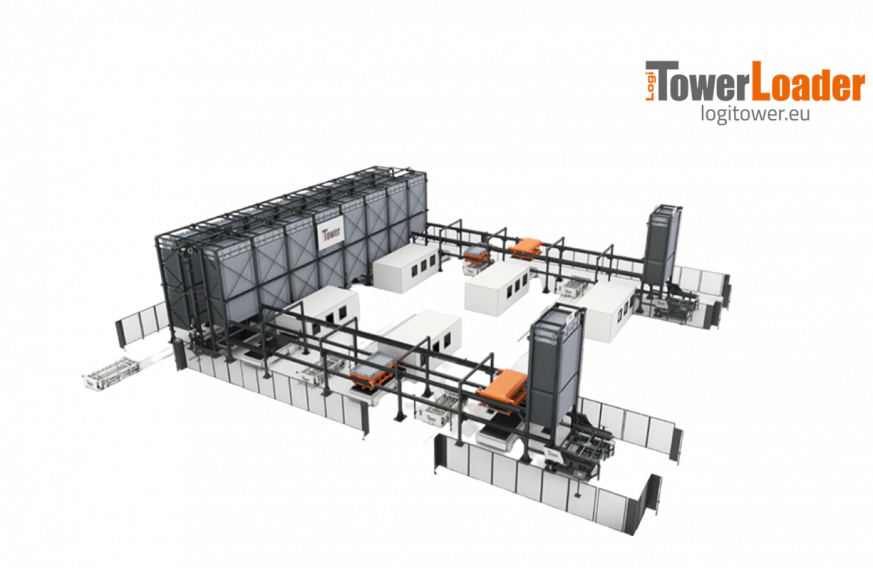

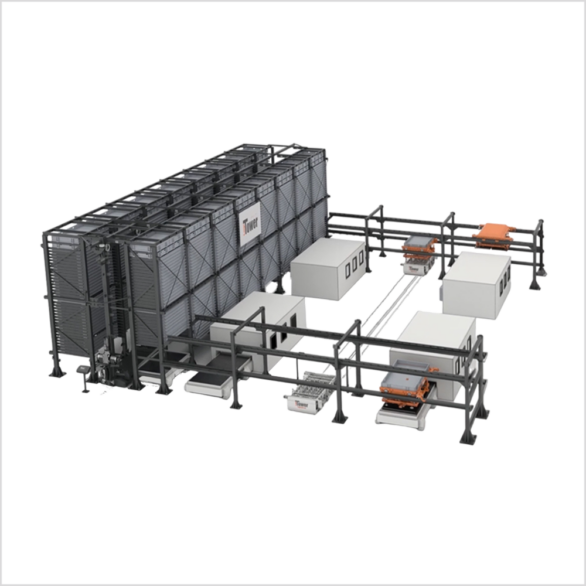

LogiTowerLoader improves a sheet metal picking process by automated picking sheet metal from the stack or LogiTower automated storage system, loading into a cnc laser cutting centre and unloading the cut elements then.

Download catalog

LogiTowerLoader improves a sheet metal picking process by automated picking sheet metal from the stack or LogiTower automated storage system, loading into a cnc laser cutting centre and unloading the cut elements then.

Download catalog