Discover benefits of using the LogiTower automated storage system with depalletiser

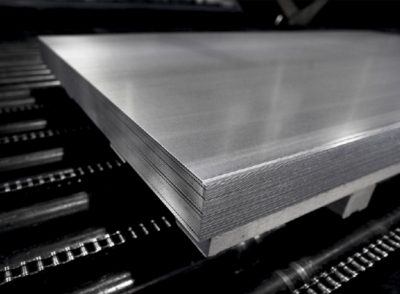

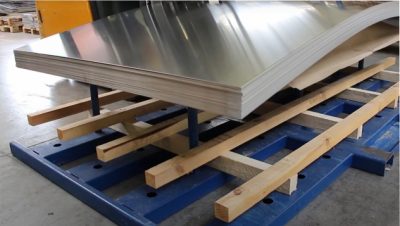

Storing heavy and untypical goods such as sheet metal and plates, panels, profiles, molds, tubes, frames and a variety of metal components can be challenging. It is necessary to handle them in a protective way and provide to operators in charge of logistics operations safe and ergonomic working conditions.

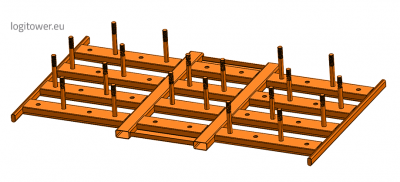

Thus, we provide to our cutomers an opportunity to integrate LogiTower automated storage system with a depalletiser, which enables fast and efficient goods unloading from pallets. In this way, even bulky, irregularly shaped materials can be removed from pallets and transferred to the rack access window then safely, easily and quickly.

The depalletiser accelerates and improves the process of loading goods into the LogiTower system.

What are advantages of integration of the LogiTower system with depalletiser option?

The depalletiser enables to get rid of unnecessary pallets from a warehouse and thus retrieve a storage space. Goods can be easily separated from pallet they are transported on and deliver directly to LogiTower automated storage system shelves then without useless pallets. In this way you can save valuable space in your warehouse or production hall and reduce time of logistic operations.

Check also: high detection space optimization.