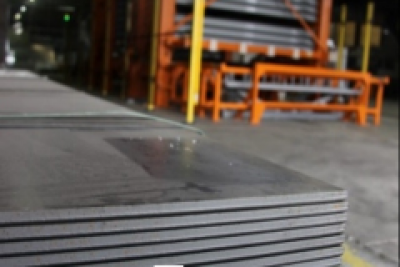

Warehouse of metal products – WIŚNIOWSKI

NewsThe role of automatic storage systems in storing metal products

The automated storage system is a perfect solution that enables to save warehouse space, which is important for companies that face its limitations. Automatic storage system allows them to reduce the use of storage space up to 80%, which translates into decreasing operating costs and fees resulting from, for example, renting a warehouse premises. It also gives an opportunity to use recovered storage space in more efficient way, and inventory increase as well.

The answer to problems with storing very large, heavy, long and untypical goods of the weight of up to 8 tons and a length of up to 12 m is the LogiTower automatic storage system, designed in accordance with individual customer guidelines, which guarantees its maximum adaptation to company needs.

LogiTower is a solution that not only saves warehouse storage space, but also increases the safety of employees and stored goods.

How to improve warehouse safety? Storing large sheet metal products or logs such as pipes, profiles, rods, etc. often generates logistical problems, such as lack of space, damage or contamination of stored elements, accidents in the warehouse or problems accessing a chosen batch of goods. LogiTower automatic storage system enables to store profiles of up to several meters long conveniently and economically. Access to particular piece of goods is maximally facilitated. System operation using the control panel is easy and intuitive, without requiring an advanced training. After selecting the appropriate name, code or icon of the item, the elevator brings it to the access point located at an ergonomic height rapidly. LogiTower can be integrated with laser (fiber) or waterjet cutting machines and works with manipulators. Loading and unloading zones can be separated, which significantly improves intralogistics and increases production efficiency.