- INDUSTRY: metal, HVAC and many others.

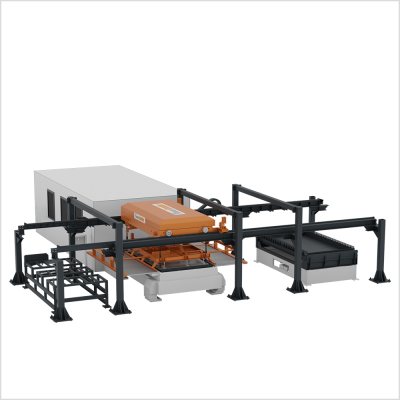

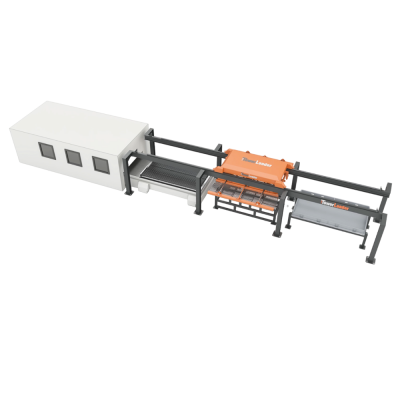

- SOLUTIONS: LogiTower and LogiTowerLoader

- APPLICATION: storage for sheet metal

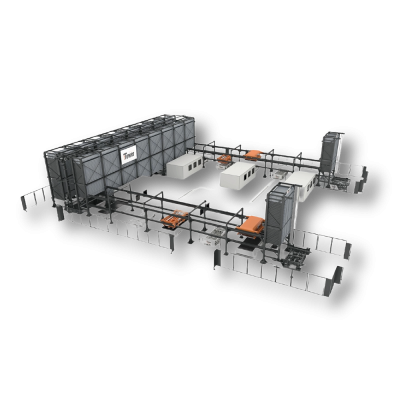

LOGITOWER INTEGRATED WITH A CUTTING CENTER

Optimize production with LogiTower and LogiTowerLoader integrated into your laser center!

Do you want to optimize your company’s production process to the maximum?

LogiTower and LogiTowerLoader are the perfect solution for you! The innovative laser center combined with an intelligent storage and loading system will not only provide you with efficiency, but also time and cost savings.

With LogiTower, you have the ability to store and manage a variety of materials in an automated manner. Now integrated with the laser center, your production process becomes even smoother and more efficient. Automatic picking and delivery of materials to the production line and precise laser cutting ensure not only speed, but also excellent product quality.

Don’t wait any longer! Choose LogiTower and LogiTowerLoader integrated with your laser center to raise your production efficiency to a new level!